Fire Road Edge Dominoes

Case Study

Children’s Hospital Of Philadelphia

Case Study

GM MultiPro Tailgate

Case Study

Why Aluminum Extrusion?

Design and produce nearly any shape—in a timely manner— through a low-cost process.

By offering designers a near net shape of their choice, aluminum extrusions are unrivaled among structural materials for design selection. The only limit is your imagination.

Aluminum & Sustainability

Lightweight, strong, durable, corrosion-resistant, versatile, low-maintenance, flexible, fast.

Aluminum extrusions help product designers, engineers, and architects get to destinations that steel can’t reach. As one of the most recycled industrial materials, it also makes a substantial contribution to sustainability efforts.

Aluminum Advantages in Sustainability

Webinar: "Finding a Path to Decarbonization with Aluminum Extrusions" - 12/9/22

Ready to get started? Find an extruder

Aluminum extrusions usage has increased from an average of about 25 pounds per North American light vehicle 10 years ago to nearly 50 pounds in 2022. And, usage is continuing to grow as automakers utilize extrusions’ light weight, strength and formability to make vehicles environmentally friendlier, safer, and increasingly personalized.

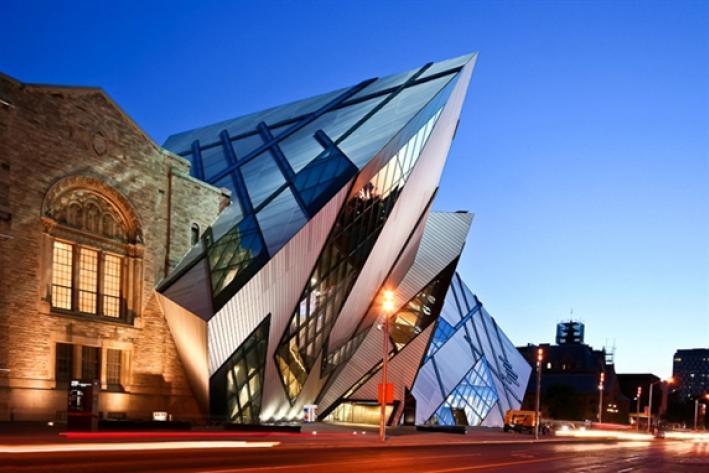

Lightweight, durable, corrosion resistant, available in an almost endless range of shapes and aesthetic finishes. No wonder architects and designers utilize aluminum extrusions in a wide range of interior and exterior building applications.

Aluminum extrusions are used for a myriad of infrastructure applications, such as this pedestrian bridge made entirely of extruded aluminum.

Registration for ET '24 - the Thirteenth International Aluminum Extrusion Technology Seminar & Exposition - is now open. Register by December 23, 2023, to realize the greatest savings.

Aluminum Extrusion Manual

191 pages of aluminum advantages, applications, sustainability, design tips, and more!